At a shield tunneling machine manufacturing facility of China Railway Engineering Equipment Group Co., Ltd. (CREG), frequent power-up failures occurred during commissioning due to severe transformer inrush currents. The repeated energization failures caused significant disruptions to the on-site installation and commissioning schedule.

China Railway Engineering Equipment Group Co., Ltd. (“CREG”), a core subsidiary of China Railway Group Limited, is a global leader in tunnel boring machine (TBM) manufacturing and service. Known as the pioneer and market leader of China’s TBM industry, CREG is one of the world’s largest TBM manufacturers, holding over 50% domestic market share for many consecutive years, with products exported to more than 30 countries and regions including Italy, France, Singapore, and Israel. CREG has broken long-term foreign monopolies, achieved full localization of TBM core technologies, and developed a series of ground breaking products such as the world’s first horseshoe-shaped TBM, rectangular pipe-jacking machine, and dual-mode TBM—filling multiple international technological gaps.

The electrical system of a TBM serves as both the “central nervous system” and the “power core,” responsible for accurate power distribution, intelligent control, and status monitoring for all major subsystems such as cutterhead drive, propulsion, screw conveyor, grouting unit, hydraulic system, and ventilation and lighting modules. If the transformer cannot be energized successfully, the commissioning progress of all these modules is delayed, and the entire machine’s delivery schedule may be affected.

To resolve this critical issue, GoLead Intelligent provided an integrated Inrush Current Suppression Cabinet solution, effectively suppressing transformer energization inrush currents from the source, and fundamentally eliminating first-energization failures. This significantly improved energization success rate and enhanced overall operational stability.

Key Project Challenges

Energization Results Using the Inrush Suppression Cabinet

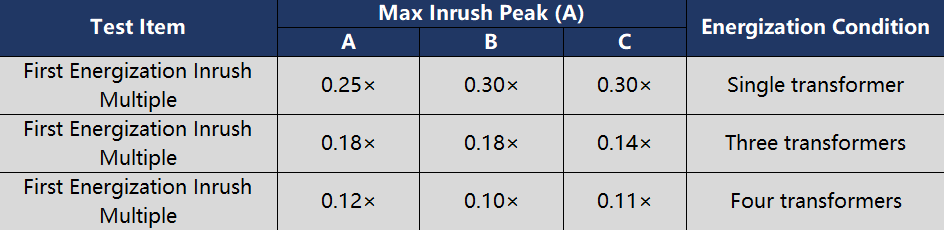

Energization tests were conducted on the TBM’s prefabricated cabin transformers. The measurements from three energization attempts are shown below:

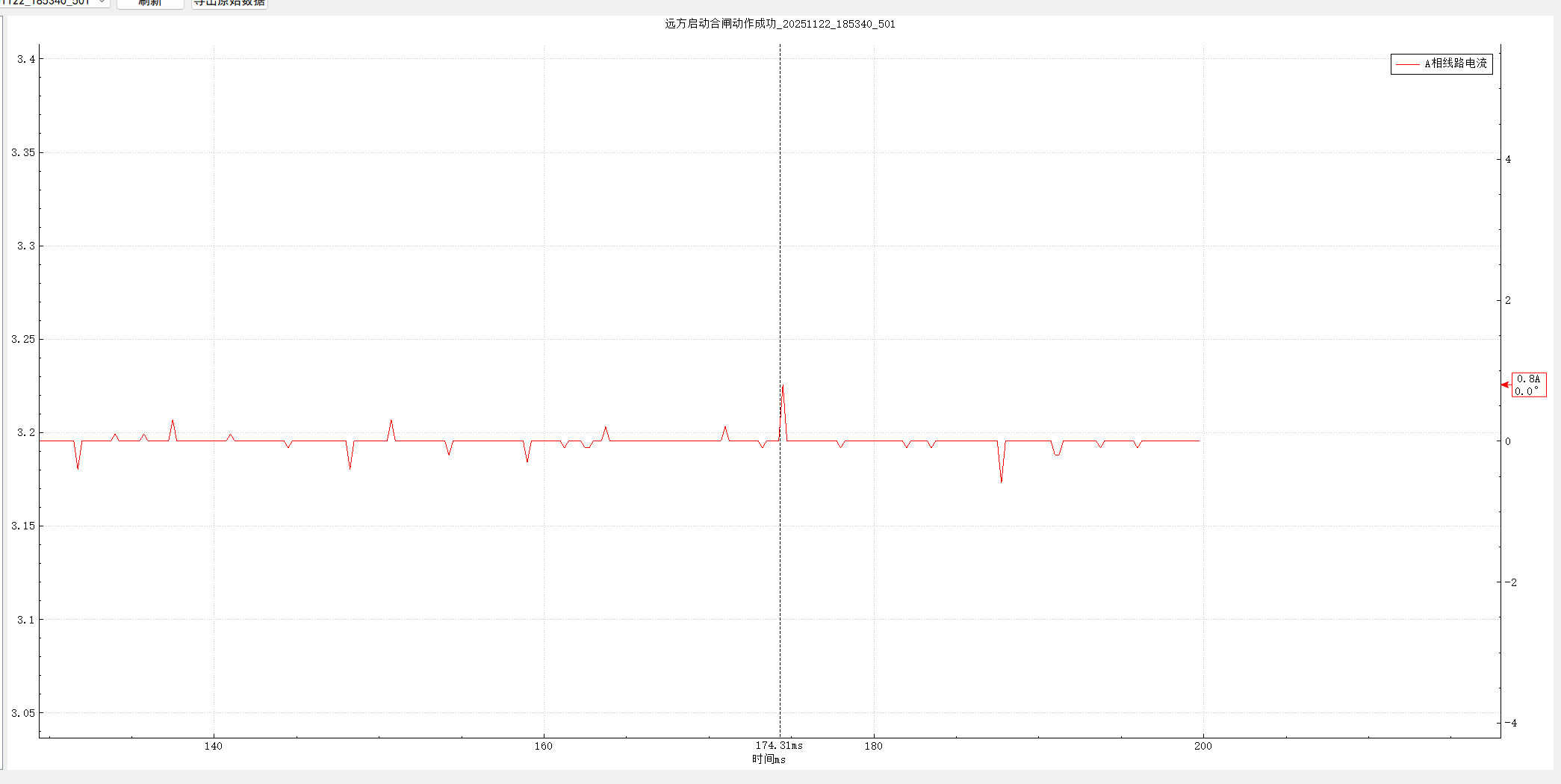

Figure 1 – Actual current waveform

Using the Inrush Current Suppression Cabinet, four transformers were successfully energized simultaneously, with the inrush current suppressed to within 0.2× of the rated peak current. Importantly, no protective relays operated, and the high-voltage switchgear in the TBM assembly workshop remained stable. The solution effectively suppressed magnetizing inrush from the root cause, eliminating power-up failures during both production and operation, and ensuring reliable power supply for the successful delivery of this national-level mega equipment.

Application Scenarios of the Integrated Inrush Suppression Cabinet

The solution is particularly suitable for demanding special-purpose scenarios, including:

By suppressing magnetizing inrush at the source, the solution greatly increases energization success rates for special-purpose equipment and ensures stable, reliable system operation.