Recently, the GLSV-ZNH1-12 Smart Phase-Controlled Circuit Breaker was successfully commissioned at a 10 kV substation of a new materials company in Inner Mongolia. By applying our innovative technology, the transformer energization inrush current was suppressed to 0.29 p.u., effectively eliminating long-standing production stoppages caused by frequent transformer switching trips.

On-Site Challenge: Inrush Current Triggering Protection Trips

The company’s 10 kV substation adopts a dual-transformer standby configuration. However, repeated failures occurred when switching to Transformer No. 2:

On-site standby power sources could not be utilized, preventing implementation of energy-saving measures

Precise Phase-Controlled Closing for Inrush Suppression and Stable Energization

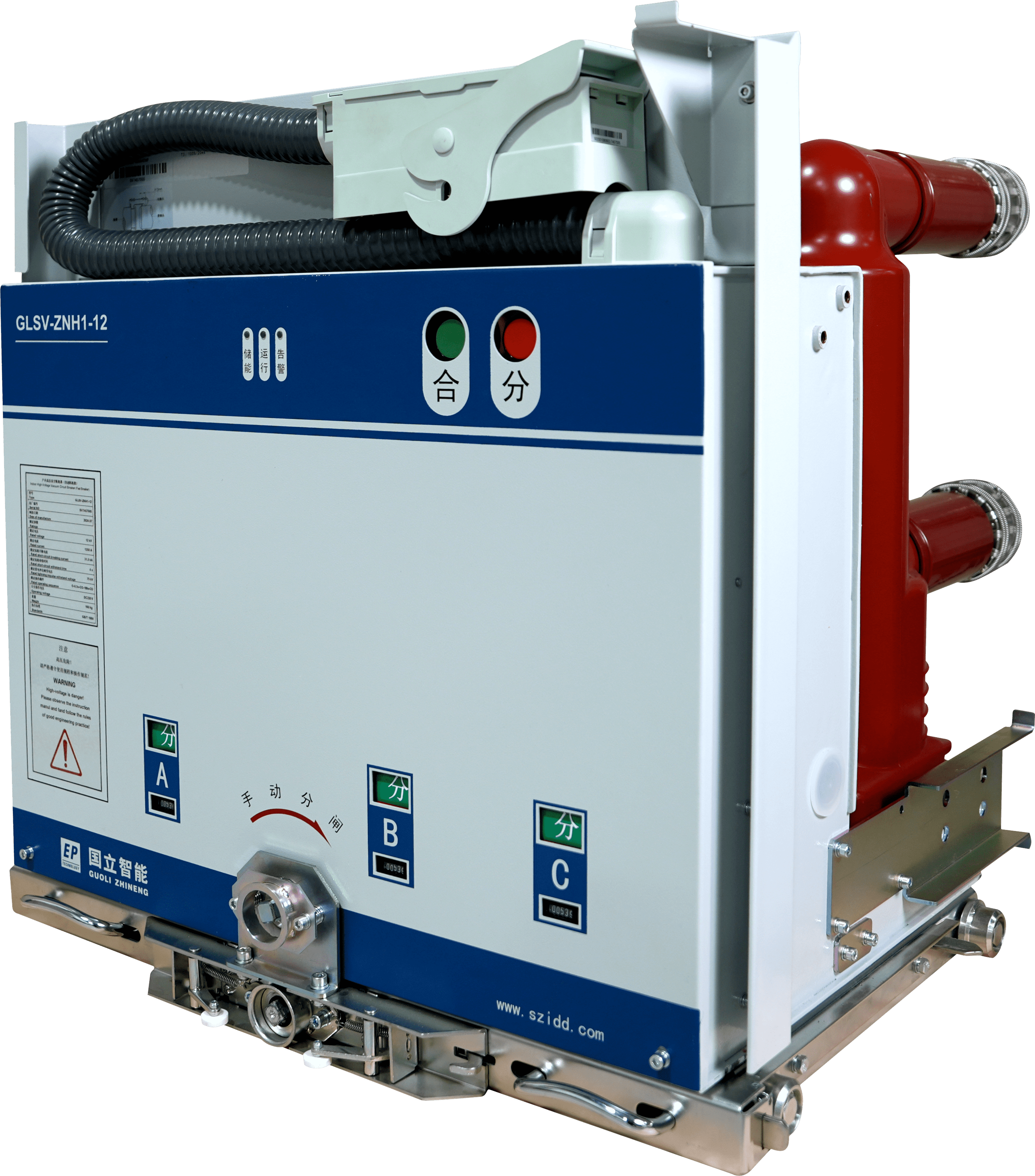

Core Solution: GLSV-ZNH1-12 Smart Phase-Controlled Circuit Breaker

Innovative Principles

The breaker precisely controls and suppresses inrush current through two proprietary technologies:

1. Zero-Flux Closing: Closing is performed at the voltage peak, corresponding to the zero magnetic flux point.

2. Residual Flux Cancellation: The polarity of transformer core residual magnetism is calculated, and reverse bias flux is generated to cancel the remaining residual flux.

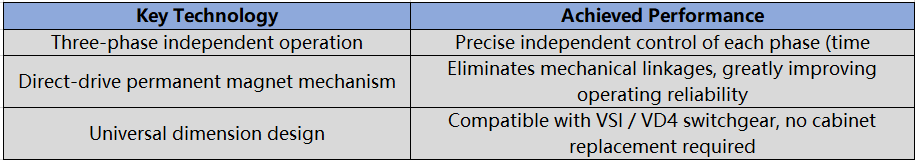

Hardware Innovations (Compared with Conventional Circuit Breakers)

Verified Results: From "Uncontrolled" Inrush to Near-Zero Impact

Comparison of Three Energization Tests

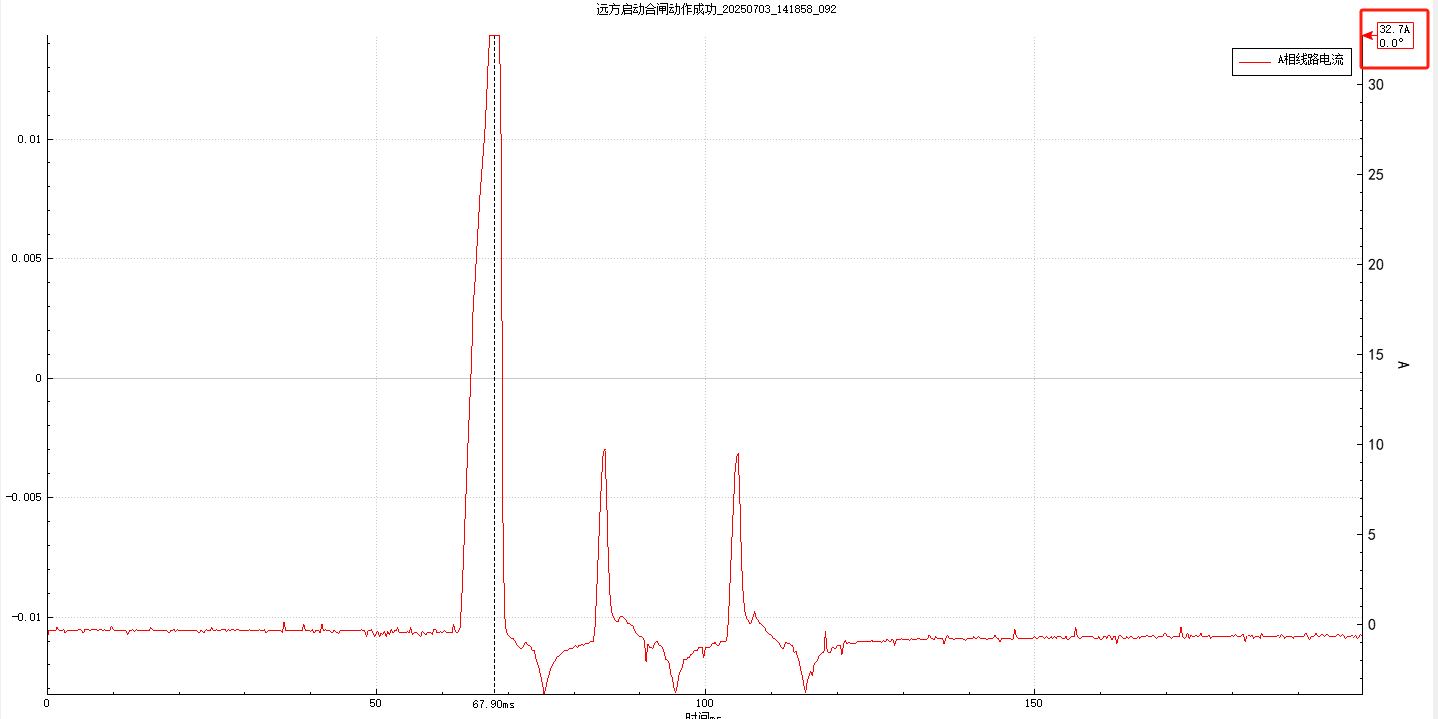

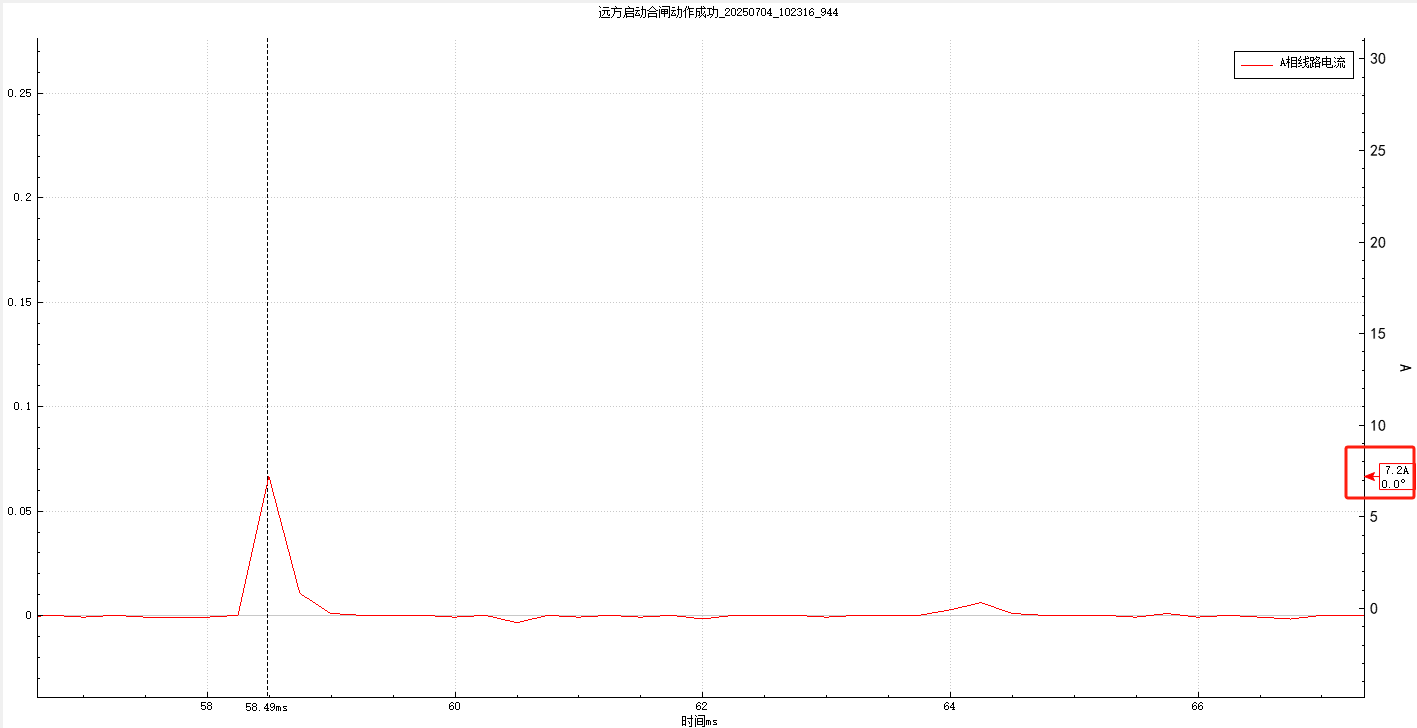

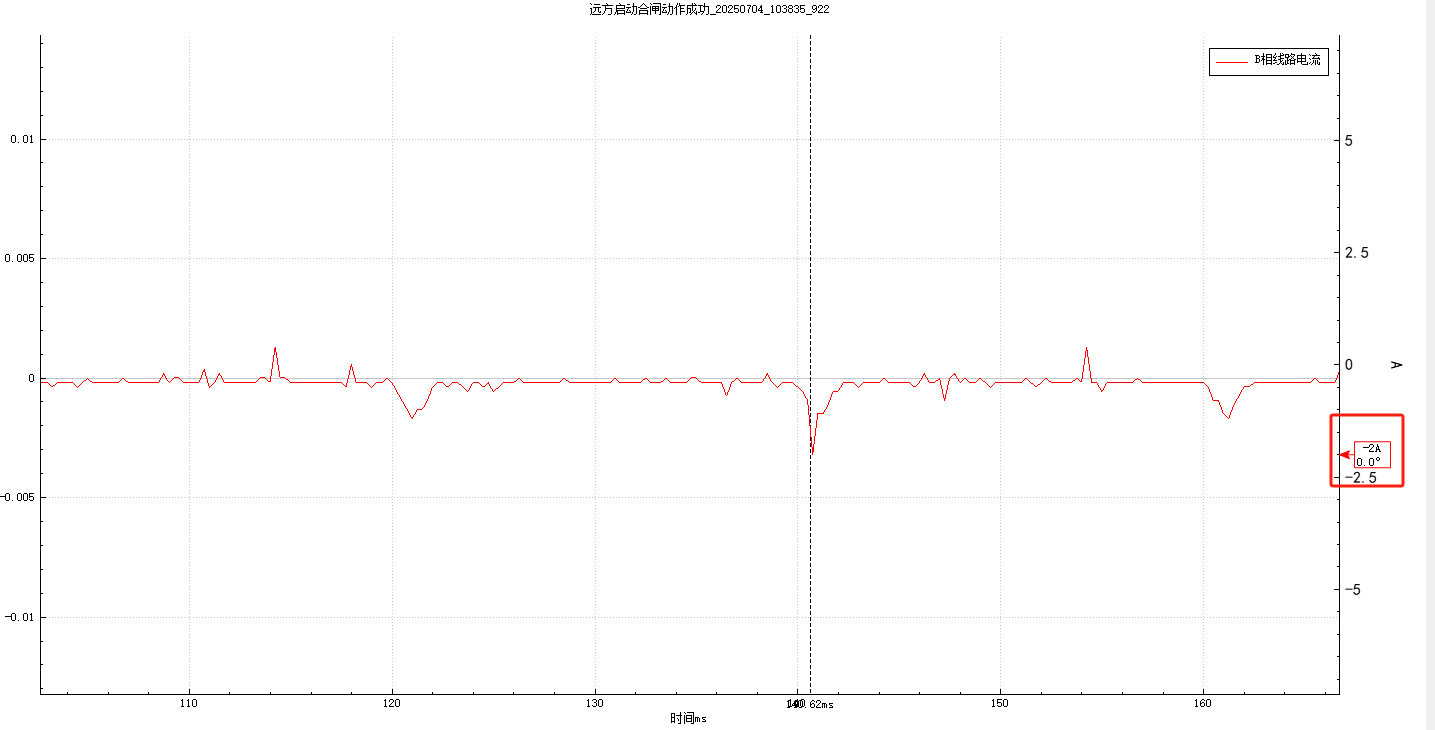

In this project, Transformer No. 2 was energized using the smart circuit breaker, with the following results:

Random Closing (Unknown Residual Flux): Under simulated random closing, the maximum phase inrush reached 4.80 p.u., far exceeding protection thresholds and triggering overcurrent tripping.

First Phase-Controlled Closing: With smart phase control, the maximum inrush was suppressed to within 1.06 p.u., achieving impact-free energization without protection operation.

Multiple Phase-Controlled Closings: In subsequent tests, the maximum inrush was consistently limited to 0.29 p.u., approaching zero-impact energization and remaining well below overcurrent protection settings.

Industry Value: Redefining the Safety Boundary of Power Equipment Switching

This project highlights three major technological trends:

1. Quantifiable Inrush Control

Precise magnetic flux compensation transforms random risks into deterministic and controllable parameters.

2. A New Path for Retrofitting Aging Substations

Universal smart circuit breakers enable in-place replacement without system reconstruction.

3. Ensured Production Continuity

Particularly suitable for industries such as metallurgy and chemicals where transformers are frequently switched.

By shifting transformer energization from a passive, high-risk process to an actively controlled operation, smart phase-controlled technology is driving the evolution of power system safety.

When transformer energization transitions from a "dangerous shock" to a "smooth transition," the Inner Mongolia project once again proves that smart phase-controlled circuit breakers not only eliminate persistent energization failures but also significantly enhance the intrinsic safety of power systems.

From repeated tripping to stable operation, this technological breakthrough provides solid assurance for production continuity. Looking ahead, with deeper adoption of this technology, it will continue to empower safe and stable operation of power equipment across multiple industries.